-

7 About

-

3 PETmarterial

-

8 Fiber series

-

6 PET packing

-

3 Protection

-

3 R & D Center

-

4 CSR

-

2 Environmental protection

Lesson 3 of Intop Class - A Practitioner of Circular Economy

发表时间 :2022-06-23

作者 :广东盈拓

This year, 2022, ushered in the twelfth year of Intop Holding.But it is actually the 22nd year that Intop has been involved in the environmental protection industry. Since the establishment of Tokzin Industrial in 2000, Intop has embarked on the road of circular economy. What may be different from other peers is that we step by step, extending from the back end to the front end, from the product application system to the front end recycling system, to create a complete PET waste plastic recycling economy system.So, what is Intop's unique waste plastic recycling economy model?In the third lesson of Intop Class, Ms. Wendy Zeng, the marketing manager, unveiled its "mystery" for us.

What is a circular economy?

Quoting the definition of circular economy by the National Development and Reform Commission: circular economy is a resource-circulating economy. It is a kind of economic growth model in line with the concept of sustainable development, with high-efficiency utilization and recycling of resources as the core, with the principle of "reduction, reuse and resource utilization", with "low consumption, low emission, high efficiency" as the basic characteristics, is a fundamental change to the traditional growth model of 'mass production, mass consumption, mass abandonment'. It originated in the 1960s by Chinese economist Kenneth Poulding.

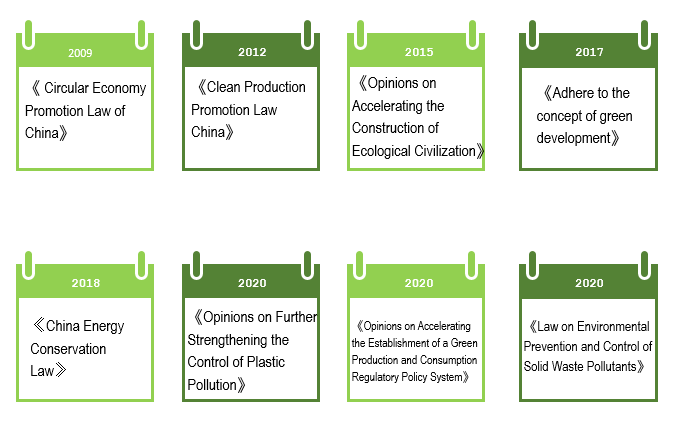

In order to promote the development of a circular economy model for waste plastics, various countries have implemented various regulations and guidelines locally.For example, the United States has the "Resource Protection and Recycling Law" and "Pollution Prevention Law", and November 15 is the recycling day; while Japan has a basic law, two comprehensive laws, and four specific laws to form a relatively Circular economy legal system; Australia, Canada, South Korea and other countries have corresponding regulations and guidelines to promote the development of circular economy.Since 2009, China has gradually issued a number of regulations to keep up with the pace of the world's implementation of circular economy, such as: "The Law of the People's Republic of China on the Promotion of Circular Economy", "Opinions on Further Strengthening the Control of Plastic Pollution", "Environmental Prevention and Control of Solids”, ”Waste Pollutants Act”, etc.

Organizations such as APR in the United States, PETCORE/PRE in Europe, Japan's PET Bottle Recycling Promotion Association, and South Korea's KPRC have launched plastic design guidelines, aiming to reduce the difficulty of plastic recycling from the source.The annual consumption of rPET in the United States is about 720,000 tons, which is the plastic variety with the highest recycling rate. In the past 10 years, the unit consumption of rPET in Europe has been reduced by 35% through lightweight PET materials; the PET recycling rate in Japan is 96.7%. These are the results of the practice of plastic recycling economy in various countries.

The European Union's MareFrame project stipulates that from 2021, the production and sale of disposable plastic products such as disposable tableware, cotton swabs, and straws will be banned; Japan's Environmental Protection Agency is a special gift to every family every year - showing the specific details of household waste in the form of cartoons, And mark in yellow and green when different wastes are discarded; and the Japanese government and AEON jointly produced about 100 sets of podiums for the Tokyo Olympics with recycled waste plastics, all of which are vivid examples of the plastic recycling economy.

At the corporate level, there are also many forward-looking domestic and foreign brand companies taking the lead in promoting circular economy: Nestlé began to abolish plastic straws in 2019, using materials such as paper and innovative designs to reduce waste; Coca-Cola plans to increase the use of recycled packaging materials to 50% by 2030; Unilever and Alibaba have jointly launched the "Plastic Removal Action" to help create a plastic recycling supply chain and create a waste-free world. Meituan Qingshan plan cooperate with Mobike to create a take-away lunch box recycled fender, and a series of take-out lunch box recycling application products jointly created by a number of companies; Watsons uses 100% recycled PET, stops the use of PVC labels, and develops refillable water machine, etc.

Since the official establishment of Guangdong Intop Industrial Holdings Co., Ltd. in 2012, the company has implemented group management. Its three wholly-owned subsidiaries are:Dongguan Tokzin Industrial Co., Ltd. (referred to as Tokzin Industrial)Xingning Tokzin Yinghui Resources Co., Ltd. (referred to as Tokzin Yinghui)Dongguan Bouteille Renewable Resources Recycling Enterprise Management Co., Ltd. (referred to as Bouteille)

Intop's unique waste plastic recycling economy model is composed of these three subsidiaries.Bouteille and its subsidiaries form the front-end recycling system in the closed loop of Intop circular economy, which is responsible for the recycling of front-end waste PET and bottle source control, laying a solid foundation for the realization of PET bottle-to-bottle recycling;Tokzin Yinghui shows the production and processing system in the closed-loop industrial chain of Intop circular economy. The pure white and blue-green bottle bales sorted and packaged from Bouteille are transported to Tokzin Yinghui, and processed into AAA grade pure white bottle flakes and blue and white bottle flakes through multiple processes for downstream customers and manufacturers to apply in different fields. Among them, AAA grade bottle flakes can be applied to blowing bottles to achieve the same level recycling application of PET;Tokzin Industrial is our product application system in the closed-loop industrial chain of Intop. After the blue and white bottle flakes of the Tokzin Industrial are transported to the Tokzin Industrial, they are processed into recycled polyester staple fibers for filling of furniture, home textiles, and toys.

The traditional mode of pet recycling and reuse is the downgraded utilization of PET; the ultimate goal of Intop is to realize the same-level utilization of PET bottle to bottle, truly realize the high-quality recycling of PET, and help promote the realization of circular economy. The key factor that determines whether the waste PET bottles can be used at the same level is the quality of the recycled bottle source, which is why Intop has built its own front-end recycling system! Bouteille has built its own recycling system at the source and set up a number of standardized green sorting centers to ensure stable and high-quality bottle sources and reduce secondary pollution, to build a new recycling traceability system combining recycling logistics + information flow to realize the online sharing of upstream and downstream data and closed-loop management.

including "Plastic Recycled Plastics Part 9: Polyethylene Terephthalate (PET) Materials", "Recyclable Design Guidelines for Polyethylene Terephthalate (PET) Container Packaging Products", we spared no effort to promote the development of industry standards, while regulating the development of enterprises ourselves.

Intop is not only the first enterprise in the Greater Bay Area to obtain the OBP certification, but also the first to start carbon footprint assessment and establish recycling demonstration sites. It hopes to publicize the environmental benefits of PET plastic recycling through its own unremitting efforts, to further cultivate and enhance consumers' awareness of environmental protection, and promote the development of PET circular economy.

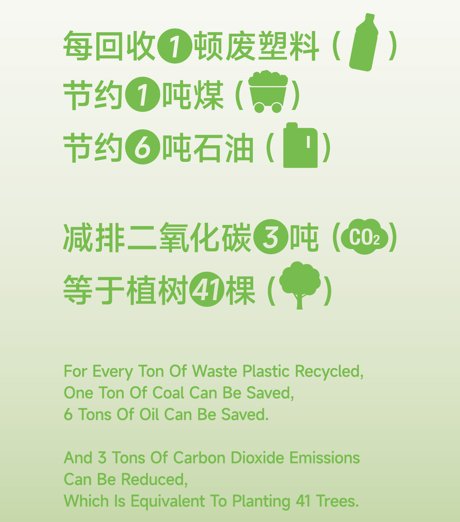

As of 2021, the subsidiaries of Intop have recycled 600,000 tons of waste plastics, produced 500,000 tons of recycled polyester staple fibers, and 100,000 tons of recycled PET bottle flakes. Calculated based on the consumption of 3 tons of crude oil for one ton of synthetic resin, it is equivalent to Saved 1.5 million tons of crude oil and reduced carbon dioxide emissions by 800,000 tons.

As Wendy introduced to us in the classroom, Intop always adheres to "developing circular economy and building green homes together" in the company's development process, and puts the promotion of circular economy development in the first place. And we, every Intop person, after a deeper understanding of the company's development policy, will be more determined to work with the company to promote the development of circular economy, Be the guardian of the environment!